- Standard Cartridge Seals

UTX

- Single seal configuration

- Unbalanced design

- Independent of direction of rotation

- Cartridge construction

Download PDF

Details

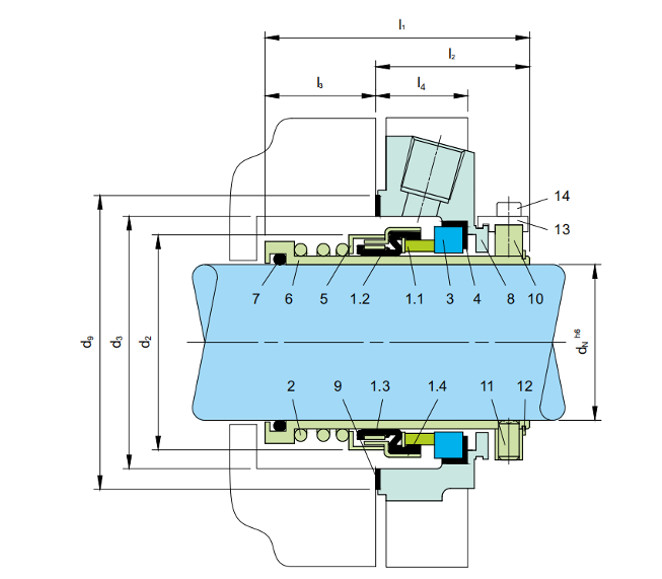

-

1

Bellows unit

-

1.1

Seal face

-

1.2

Bellows

-

1.3

Drive collar

-

1.4

L-ring (spring collar)

-

2

Spring

-

3

Seat

-

4

O-ring or L-ring

-

5

Spacer ring

-

6

Shaft sleeve

-

7

O-Ring

-

8

Cover

-

9

Gasket

-

10

Drive collar

-

11

Set screw

-

12

Snap ring

-

13

Assembly fixture

-

14

HSH Cap Screw

- Ideal for use in process pump standardization

- Flushing connection according to API 682, Plan 11 for seal chamber cleaning and cooling

- Low cost cartridge solution

- Dimensional modification of the stuffing chamber is not required due to short radial installation height

- Ideal to convert and retrofit pumps with packings and large volume OEM production

- Cartridge unit factory assembled for easy installation, which reduces downtime

- Rugged design for long operating life

- Water and waste water technology

- Sewage water

- Cold and hot water

- Cooling fluids

- Beverages

- Circulating pumps

- Water and waste water pumps

- Seal face: Carbon graphite resin impregnated (B), Silicon carbide (Q1)

- Seat: Silicon carbide (Q1)

- Secondary seals: FKM (V), EPDM (E)

- Metal parts: CrNiMo steel (G),CrNiMo cast steel (G)

- Sizes: Upto 75 mm (1″ … 2.625″)

- Pressure: p1 = 12 bar (174 PSI)

- Temperature: t = – 20 °C…+ 140 °C

(- 4 °F…+284 °F) - Speed = 10 m/s (33 ft/s)

- Axial movement: ± 0.5 mm

Other products

-

U300N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts

Learn more

-

U200N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts…

Learn more

-

UG943

Single seal configuration, Unbalanced design, Independent of direction of rotation, For plain…

Learn more

-

UR-D

Dual seal configuration, Unbalanced design, Independent of direction of rotation…

Learn more