- Mechanical Seals For Agitators, Mixers, Kneaders & Reactors

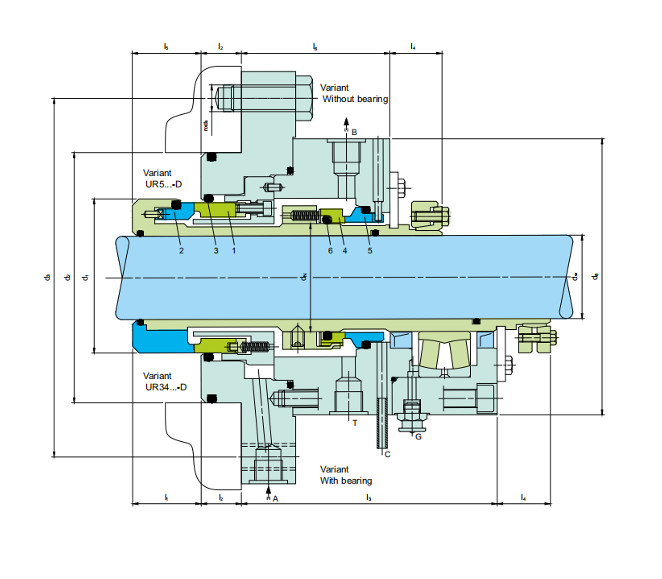

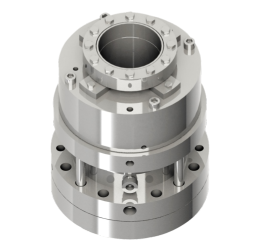

UR-D

- Dual seal configuration

- Unbalanced design

- Independent of direction of rotation

- Cartridge construction

- Designed for top, side and bottom entry vessels

- Design of the product side seat is rotary

Download PDF

Details

-

1

Seal face, product side

-

2

Seat, product side

-

3

O-Ring, dynamic

-

4

Seal face, atmosphere side

-

5

Seat, atmosphere side

-

6

O-Ring, dynamic

- Design with CIP-/SIP (Cleaning in Place, Sterilization in Place)

- Smooth construction of surfaces with no empty crevices

- Sterile application design available

- Rugged design to ensure long term reliability and operating life

- Seals are assembled in cartridge construction for easy fitment

- Over all connecting dimensions are tailor made to customer’s specifications

- Chemical industry

- Food and beverage industry

- Pharmaceutical industry

- Dryers

- Kneaders

- Mills

- Mixers

- Pressure filters

- Reactors

- Product side :

Seal face, seat: Silicon carbide (Q1),

Tungsten carbide (U) - Metal parts: Cr steel (E), CrNiMo steel (G), Hastelloy® (M)

- Atmosphere side:

Seal face, seat: Silicon carbide (Q1), Carbon graphite resin impregnated (B)

Metal parts: Cr steel (E), CrNiMo steel (G) - Product and atmosphere side:

Springs: CrNiMo steel (G), Hastelloy® (M) - Secondary seals: EPDM (E), FKM (V),

FFKM (K), FKM, FEP wrapped (M5)

Other materials on request.

- Sizes:

dN/dw = Upto 200 (500) mm (Upto 7.875” (20.00”) - Axial offset shaft/housing:

dN/dw 30 … 60 mm (1.18” …2.36”):

max. ±1.5 mm (0.059”) - dN/dw >60 mm (2.36”):

max. ±2.0 mm (0.079”) Radial offset shaft/housing: max. ±0.3 mm (0.012”) - Pressure:

p1 (media) = vacuum … 14 (23) bar (203 (334 PSI))

p3 (buffer fluid) = max. 16 (25) bar (232 (363 PSI))

Δ p3 > p1 = min. 2 bar (29 PSI), max. 10 bar (145 PSI) - Temperature:

t1 (media) = -20 °C … +200 (300) °C (-4 °F … +392 (572) °F) Speed = 20 m/s (66 ft/s)

- Options:

Cooling or heating flange

Temperature probe

Axial expansion joint (shaft lifting)

Wiper ring (shaft lifting)

- FDA

Other products

-

U300N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts

Learn more

-

U200N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts…

Learn more

-

UG943

Single seal configuration, Unbalanced design, Independent of direction of rotation, For plain…

Learn more

-

BSH-D

Dual seal configuration, Balanced design, Independent of direction of rotation, Cartridge construction…

Learn more