- Split Seals

SPX

- Single seal in split configuration

- Balanced design

- Independent of direction of rotation

- For plain shafts

- Semi-cartridge construction

- Built-in flushing connections

- Designed with external pressurization

- Factory assembled fully split single seal, 2 x 2 segments

- Stationary design with multiple springs

Download PDF

Details

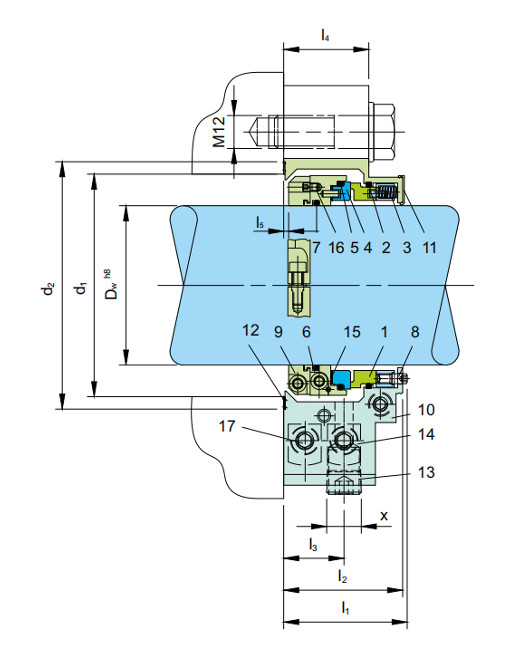

-

1

Seal face

-

2,5,7

O-ring

-

3

Spring

-

4

Seat

-

6

Driver

-

8

Thrust ring

-

9

Clamp collar

-

10

Housing

-

11

Assembly fixture

-

12,15

Gasket

-

13

Head screw plug

-

14

Mounting plate

-

16

Set screw

-

17

Socket head screw

- Economical to assemble as the complete dismantling of the equipment is not necessary to install the seal

- Reduces down time due to ease in installation

- Rugged seal construction

- Distortion of the seat is avoided by mechanical decoupling of the clamping ring

- Ease in installation due and no modifications are required because the seal is located outside of the stuffing box

- Due to the stationary design and the elastic seat mounting a high tolerance of shaft deflections can be accommodated

- Low leakage is achieved by the elimination of secondary seals which eliminates leakage paths between split components

- Shaft is protected by uniform torque transmission through the clamping ring which prevents damage caused by set screws.

- Springs are product protected to avoid contamination and clogging

- Agitators

- Chemical Industry

- Centrifugal pumps

- Conveying pulp with stock pumps

- Cooling water pumps for energy generation

- Conveying timber to refiners with pumping screws

- Circulation of pulp-and-water mixtures in storage vessels

- Displacement pumps

- Process industry

- Petrochemical Industry

- Power Plant Technology

- Pulp and paper industry

- Pump stations for waste water treatment

- Seal face: Carbon graphite antimony impregnated (A), Silicon carbide (Q2)

- Seat: Silicon carbide (Q2)

- Secondary seals: FKM (V), EPDM (E), NBR(P)

- Springs: CrNiMo steel (G)

- Metal parts: CrNiMo steel (G)

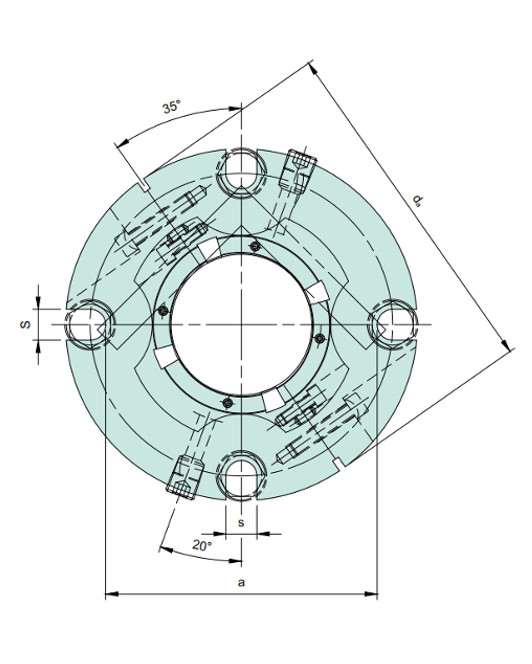

- Shaft diameter: d1 = Upto…150mm (Upto… 6.000’’)

- Pressure: p1 = 10 bar (145 PSI)

- Temperature: t = -40 °C… +150 °C (- 40 °F… + 300 °F),

above 80 °C (175 °F) flush is recommended - Speed = 10 m/s (33 ft/s)

- Axial movement: ± 1.5 mm (1/16″)

- Radial movement: ± 0.8 mm (1/32″)

Other products

-

U300N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts

Learn more

-

U200N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts…

Learn more

-

UG943

Single seal configuration, Unbalanced design, Independent of direction of rotation, For plain…

Learn more

-

UR-D

Dual seal configuration, Unbalanced design, Independent of direction of rotation…

Learn more