- Gas Lubricated Seals for Pumps & Agitators

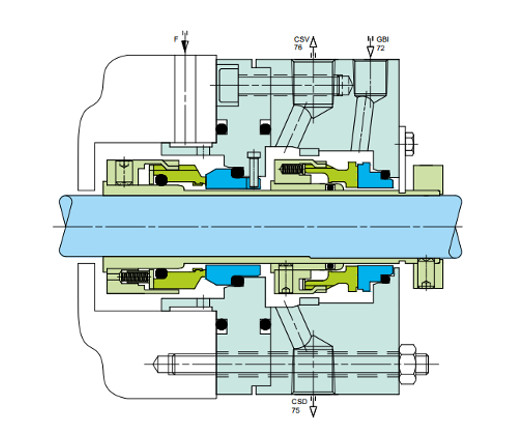

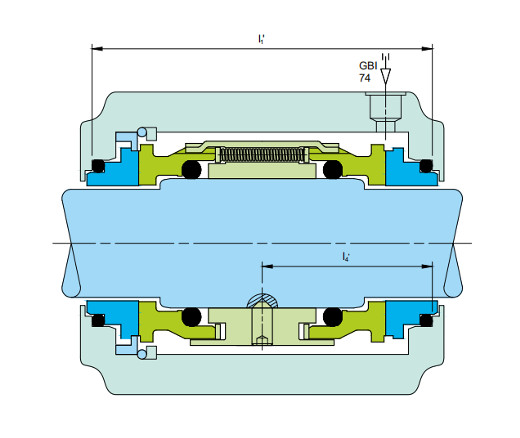

GSPH-K

- Single and Dual seal configuration

- Balanced design

- For stepped shafts

- Rotary unit with multiple springs

- Designed to remain in closed position in the event of buffer pressure failure

- Can accommodate reverse pressure

- Gas-lubricated design

- Gas grooves design is available in Vgrooves and U-grooves (independent of direction of rotation)

Download PDF

Details

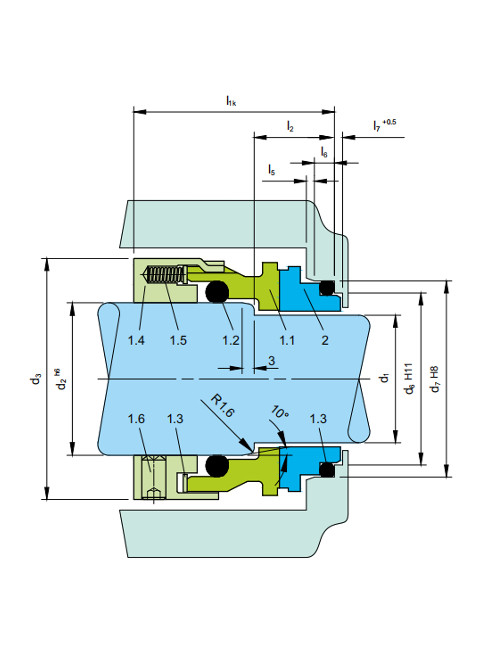

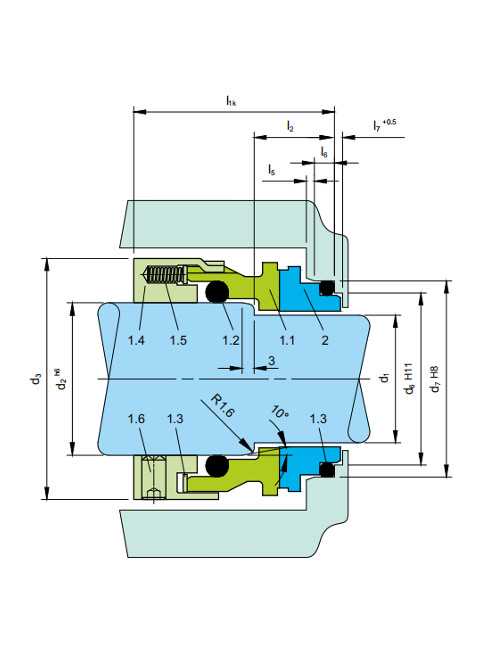

-

1.1

Sliding face

-

1.2

O-Ring

-

1.3

Thrust ring

-

1.4

Drive collar

-

1.5

Spring

-

1.6

Set screw

-

2

Seat

-

3

O-Ring

- Seal faces are designed to be noncontacting during operation

- Designed for environmental protection with high efficiency

- Due to non-contacting design there is no friction on the seal faces and there is no heat generated at the seal or in the medium

- Trouble free operations as complex components are not required to dissipate frictional heat

- Differential pressure not required with hard / soft material combination

- Conforms to containment seal in accordance with API 682

- Chemical industry

- Refining technology

- Gases and liquids(single seals only gas)

- Gases and liquids which must not get into the atmosphere (dual seal)

- Gases not harmful to the environment (single seal)

- Fans

- Small steam turbines

- Blowers

- Roots compressors

- Pumps

- Seal face: Carbon graphite antimony impregnated (A),

Silicon carbide (Q2),alternatively: Carbon graphite resin

impregnated (B), Silicon carbide (Q1) Seat: Silicon carbide (Q1, Q2),

Silicon carbide (Q19, Q29) with seal face in Q1 resp. Q2 - Metal parts: CrNiMo steel (G)

- Shaft diameter: d = 28 … 125 mm (1.10″ … 4.92″)

- Pressure: p = 25 bar (363 PSI)

- Temperature: t* = -20 °C…+170 °C (-4 °F…+338 °F)

- Sliding velocity: v = 4 … 25 m/s (13 … 82 ft/s)

* Depending on resistance of O-rings

- EN 12756

- API 682 / ISO 21049

Other products

-

U300N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts

Learn more

-

U200N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts…

Learn more

-

UG943

Single seal configuration, Unbalanced design, Independent of direction of rotation, For plain…

Learn more

-

UR-D

Dual seal configuration, Unbalanced design, Independent of direction of rotation…

Learn more