- Split Seals

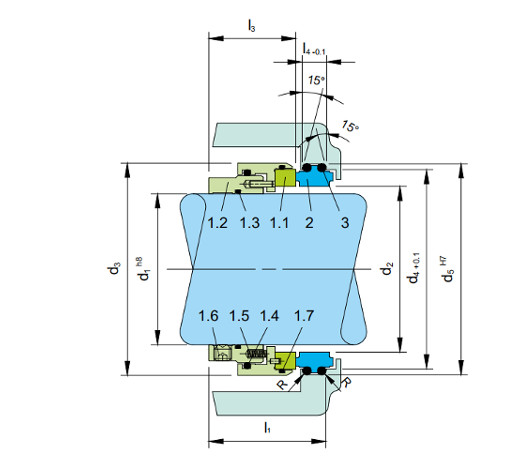

BGH201

- Single seal in semi split configuration

- Balanced design

- Independent of direction of rotation

- For plain shafts

- Rotary unit with multiple springs

Download PDF

Details

-

1.1

Seal face *

-

1.2

Drive collar

-

1.3

O-ring *

-

1.4

O-ring

-

1.5

Spring

-

1.6

Set screw

-

1.7

O-ring *

-

2

Stationary Seat *

-

3

O-ring *

-

Note

*For disassembly of unsplit seal faces, seats and O-Ring should be broken or cut.

- Economical to assemble as the complete dismantling of the equipment is not necessary to install the seal

- Reduces down time due to ease in installation

- Rugged seal construction

- Versatile split seat can be used on both the sides

- Springs are product protected to avoid contamination

- Chest agitators

- Cooling water pumps

- Defibrators

- Gears

- Power plant technology

- Pulp and paper industry

- Sea water desalination

- Shipbuilding

- Stern tubes

- Water and waste water technology

- Water turbines

- Seal face: Silicon carbide (Q1)

- Seat: Silicon carbide (Q1, Q2), Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B)

- Secondary seals: FKM (V), EPDM (E), NBR (P) Metal parts: CrNiMo steel (G)

- Sizes: d1 = Upto 310 mm (Upto 12.250’’)

- Pressure: p1 = 25 bar (363 PSI)

- Temperature: t1 = 150 °C (302 °F)

- Speed = 20 m/s (66 ft/s)

- Permissible axial movement: ± 2.0 mm

Other products

-

U300N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts

Learn more

-

U200N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts…

Learn more

-

UG943

Single seal configuration, Unbalanced design, Independent of direction of rotation, For plain…

Learn more

-

UR-D

Dual seal configuration, Unbalanced design, Independent of direction of rotation…

Learn more