- Supply Systems & Components

BFS 54

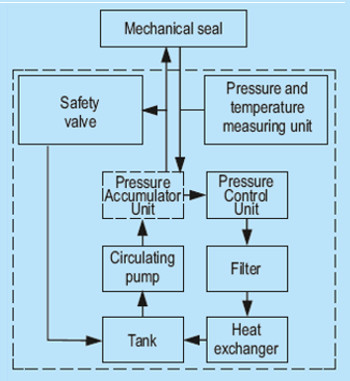

BFS range of barrier pressure units are designed to perform various functions of a barrier system which is essential for operating double seals (circulation and cooling of the barrier medium, pressurization of the barrier fluid and compensation of leakage). The BFS systems are designed to operate with hydraulic oil having viscosity values ranging from 12 to 90 mm2/s under normal operating temperature of the equipment. The final selection of optimum viscosity of the oil to be used has to be ascertained independently in accordance with the respective operating parameters of the equipment

Download PDF

Details

- For reducing barrier fluid pressure at standstill an automatic relief valve is provided

- Reversible double filter is provided for the fluid to pass through the oil cooler

- Level Switch with contact for minimum level

- Barrier fluid pressure can be controlled manually

- Maximum operating temperature in the tank to be maintained at 80 oC (return line maximum 90 oC)

- For monitoring the pump discharge pressure (outside the circuit) an additional pressure connection is provided

- Temperature monitoring is achieved by providing a return line and tank thermometer

- The barrier pressure for circulation is generated by a gear pump. The setpoint barrier pressure is set on an overflow valve in the mechanical seal return line. From this point on the barrier fluid flows back without pressure through a filter and a heat exchanger to the storage tank. To enable systems (pump, agitator) to be stopped without causing damage to the seal in the event of a malfunction (e.g. power failure, damaged motor, etc.), the barrier pressure unit can be fitted with a pressure accumulator unit. To prevent the pressure in the accumulator discharging to the pressureless storage tank, the return line has a pilot-operated check valve, and the supply line also has a simple check valve. The barrier pressure is retained for a limited time. However, no circulation takes place and no heat is dissipated from the mechanical seal.

- Chemical industry

- Oil and gas industry

- Petrochemical industry

- Refining technology

Other products

-

U300N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts

Learn more

-

U200N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts…

Learn more

-

UG943

Single seal configuration, Unbalanced design, Independent of direction of rotation, For plain…

Learn more

-

UR-D

Dual seal configuration, Unbalanced design, Independent of direction of rotation…

Learn more