- Supply Systems & Components

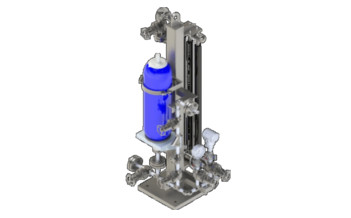

BFS 53B

- Circulation in accordance with API 682 / ISO 21049: Plan 53B

- Pressurised barrier system (closed circuit) is employed for applications in sealing systems with operating parameters of high pressures and/or for hazardous/environmentally harmful processes. The BFS (Plan 53B) range is available with a pressure accumulator, cooler (finned tube or water or air cooler with fan) with a wide range of instruments.

Download PDF

Details

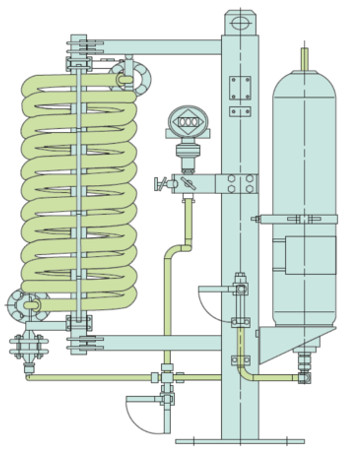

- Design construction available with finned tube, water or air coolers with fan

- Barrier pressure is created without any need for connection to a nitrogen supply

- Modular design combination available with a wide variety of system components and instruments selection possible

- Pressurisation is achieved through a pre-loaded bladder accumulator

- Nitrogen cannot get into the barrier medium or process medium, because it is separated from the barrier medium by membranes in the accumulator

- The BFS is designed to perform the following functions of a barrier system:

- To pressurize the barrier chamber

- Leakage compensation

- To cool the seal

- Pressurization (> process pressure) prevents the process medium from getting into the barrier circuit or the atmosphere. Pressurization is supplied by a pressure accumulator which is pre-loaded with nitrogen. Circulation in the barrier circuit takes place by the thermosiphon principle or by forced circulation, e.g. with a pumping screw.

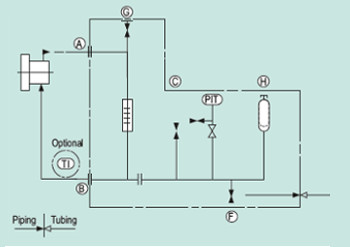

- Operating and installation diagram for a BFS (Plan 53B).

- A. From mechanical seal

- B. To mechanical seal

- C. Fill

- F. Drain

- G. Vent

- H. N2 Precharge

- Chemical industry

- Oil and gas industry

- Petrochemical industry

- Refining technology

- PED 2014/68/EU (Design and production in accordance with EU Pressure Equipment Directive)

- ASME VIII, Div. 1 (Design, calculation and production)

Other products

-

U300N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts

Learn more

-

U200N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts…

Learn more

-

UG943

Single seal configuration, Unbalanced design, Independent of direction of rotation, For plain…

Learn more

-

UR-D

Dual seal configuration, Unbalanced design, Independent of direction of rotation…

Learn more