- API 682 4th Edition

UFL850 Single Seal

- API 682 Category 2 and 3, Type B, Arrangement 1 seal

- Single seal configuration

- Balanced design

- Independent of direction of rotation

- Cartridge Construction

- For plain shafts

- Rotary metal bellows design

- Shrink fitted seal ring and solid stationary ring

Download PDF

Details

-

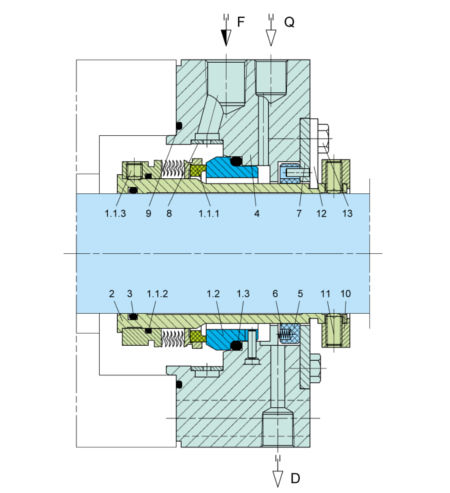

1.1.1

Seal Ring with Bellows Unit

-

1.1.2,1.3,3,9

O-ring

-

1.1.3,11

Set screw

-

1.2

Mating ring

-

2

Shaft sleeve

-

4

Gland

-

5

Throttle bushing

-

6

Spring

-

7

Washer

-

8

Multi-flow distributor

-

10

Set ring

-

12

Setting plate

-

13

Hexagon bolt

-

f

Flush

-

q

Quench

-

d

Drain

- Compact design construction

- Balanced bellows design allows installation on plain sleeve

- Elimination of seal face hang up due to absence of dynamic O-Ring

- Face load variation is minimised due to bellows design on account of shaft expansion or face wear

- Resistance to abrasive particles in the medium, no shaft or sleeve fretting

- Narrow seal face width leads to low heat generation and power consumption

- Extended seal life

- API 610/ISO 13709 pumps

- Refining technology

- Oil and gas industry

- Petrochemical industry

- Chemical industry

- Power plant technology

- LPG plants

- Process pumps

- Seal ring: Blister resistant carbon

- Mating ring: Silicon carbide SSiC (Q1), RBSiC (Q2)

- Bellows: Hastelloy ® C-276 (M5)

- Option: Inconel® 718 (M6)

- Secondary seals: EPDM (E), NBR (P), FKM (V), FFKM (K)

- Metal parts: CrNiMo steel 316 (G), Hastelloy ® C-276 (M5)

- Shaft diameter:

d1 = 20 … 110 mm (0.79″ … 4.33″) - Pressure:

p = vacuum … 20 bar (290 PSI) - Temperature:

t = –40 °C … +200 °C (–40 °F … +392 °F) - Sliding velocity:

vg … 23 m/s (75ft/s)

- Process side:

01, 02, 03, 11, 12, 13, 14, 21, 22, 23, 31, 32, 41

Atmospheric side: 51, 61, 62, 65A, 65B, 66A, 66B

Other products

-

U300N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts

Learn more

-

U200N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts…

Learn more

-

UG943

Single seal configuration, Unbalanced design, Independent of direction of rotation, For plain…

Learn more

-

UR-D

Dual seal configuration, Unbalanced design, Independent of direction of rotation…

Learn more