- Supply Systems & Components

CS

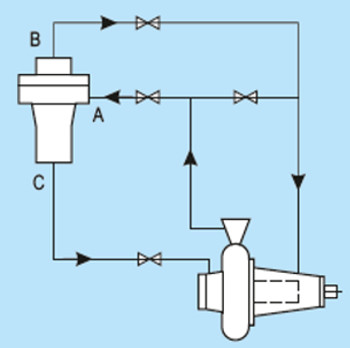

- Circulation in accordance with API 682 / ISO 21049: Plan 31, Plan 41

- The CS range is available in varied versions i.e. cyclone separator with replaceable insert made of ceramic or cast version of the cyclone separator or cyclone separator for high flow rates and high pressures.

Download PDF

Details

-

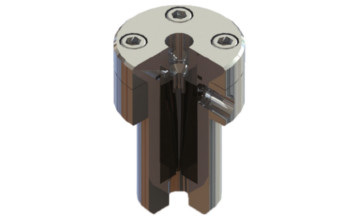

1

Housing

-

2

Cover

-

3

Insert

-

4

O-Ring

- Construction design for operating pressure up to 200 bar

- Hassle free maintenance is achieved in operation with high reliability, because the dirt is automatically conveyed to the suction nozzle of the pump

- High filtration efficiency

- Compact design is achieved because of low space requirement, in addition to the option of block-type design with integrated flange connections

- Design allows for varied applications due to construction in stainless steel with replaceable insert made of ceramic

- Cyclone separators of the CS range are used to clean mainly aqueous liquids containing dirt and solids (e.g. in circulation systems of sewage, sludge or pipeline pumps). The best possible filtration efficiency is achieved when the specific weight of the solids is much higher than that of the carrier liquid, and when the differential pressure is as large as possible within the permissible pressure range (min. 1.7 bar in accordance with API 682). The viscosity of the medium is also a factor that needs to be taken into account.

- The cyclone separator must always be installed in the vertical position. The pressure at the outlets (C) and (B) must be lower than at the inlet (A). Cleaned liquid is conveyed to the top (B) and the separated dirt to the suction port of the pump.

- Chemical industry

- Oil and gas industry

- Petrochemical industry

- Refining technology

- Water and waste water technology

Other products

-

U300N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts

Learn more

-

U200N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts…

Learn more

-

UG943

Single seal configuration, Unbalanced design, Independent of direction of rotation, For plain…

Learn more

-

UR-D

Dual seal configuration, Unbalanced design, Independent of direction of rotation…

Learn more