- Standard Mechanical Seals For Pumps & Compressors

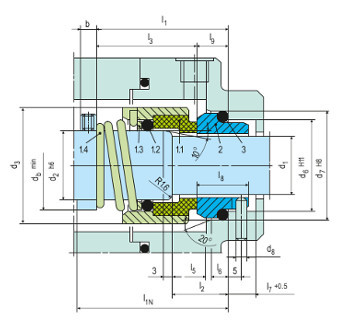

B120N

- Single seal configuration

- Balanced Design

- Dependent of direction of rotation

- For stepped shafts

- Torque transmission is through the conical spring

Download PDF

Details

-

1.1

Seal face

-

1.2

O-Ring

-

1.3

Thrust ring

-

1.4

Right Hand Spring

-

1.4

Left Hand Spring

-

2

Seat (G9)

-

3

O-Ring

- Low cost seal solution

- No damage to the shaft

- Short installation length available on request

- Chemical industry

- Hot water

- Medias with Low solids content(B170GN)

- Water and waste water technology

- Chemical standard pumps

- Water and sewage pumps

- Seal face: Carbon graphite antimony impregnated (A)

- Seat G9: Silicon carbide (Q1), Special cast CrMo steel (S)

- Sizes: d1 = Upto 80 mm (Upto 3.15’’)

- Pressure: p1 = 25 bar (363 PSI)

- Temperature: t = -50 °C…+220 °C (-58 °F…+430 °F)

- Speed = 15 m/s (50 ft/s)

- Permissible axial movement: ± 1.0 mm

- EN 12756

Other products

-

U300N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts

Learn more

-

U200N

Single seal configuration, Unbalanced Design, Dependent of direction of rotation, For plain shafts…

Learn more

-

UG943

Single seal configuration, Unbalanced design, Independent of direction of rotation, For plain…

Learn more

-

UR-D

Dual seal configuration, Unbalanced design, Independent of direction of rotation…

Learn more